Precision machining of all types

Thanks to the most modern Relais Control tool technology, we can process all materials commonly used in power plant and plant construction. We solve special tasks directly in our workshop. Of course, all work steps are defined beforehand and carried out, monitored and documented in accordance with the corresponding quality standards.

Design and calculation

Our services include the design and calculation of valves and pressure vessels with the aid of CAD systems and 3D modulation and calculation programs (Inventor) and are based on our TÜV certification as a valve manufacturer (Module G).

- Flanges

- Covers/closures

- Sealing and functional surfaces

- Punching/ Reworking of valve seats and welded sockets

- Surface welding

- Coating tungsten carbide

- Individual production according to drawing

- Series production

- Custom-made products

- Material types from simple steel to high-alloy steel such as titanium, alloy, hastelloy etc.

- Tensionable plastics (non-metallic)

- Construction of complete plants

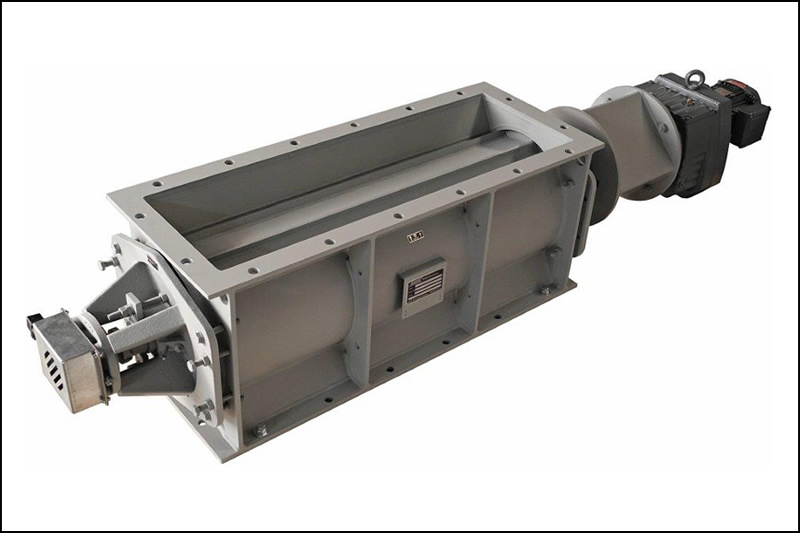

- Production of valves according to Module G

- Stationary machinery

Stationary machinery

- CNC lathe

- CNC manufacturing centre

- Carousel lathe

- Boring mill

- Radial drilling machine

- Milling machine

- Conventional lathe

Mobile machinery

- Slide grinding and lapping machines

- Valve grinding and lapping machines

- Portable lathes

- Flange and processing machines

- Seat machining equipment

- Hydraulic tools

- Welding machines

- Workshop and tool container

- Sandblasting equipment

- Safety valve testing equipment

- Pressure and leak test stands