In addition to the reworking of your work pieces, we naturally take care of the cleaning of your production equipment or moulds. The removal of resins and/or release agents requires especially careful and meticulous work processes.

We perform these tasks as required by:

- manual processing by hand

- blasting with dry ice

- (residue-free resin removal)

- laser cleaning (for surface cleaning)

We extend the operating lifetime of your production equipment and maintain its precision and accuracy

The mechanical machining of CFRP composites is carried out with the utmost precision and care. State-of-the-art equipment and motivated employees who know their trade are also available to solve your tasks. The removal of resins and/or release agents requires particularly gentle and careful work processes.

We perform these tasks as required by:

- machining and milling work (up to 60,000 rpm)

- drilling

- sawing

- grinding

All necessary facilities for further processing and testing are available as well as the special tools which are required.

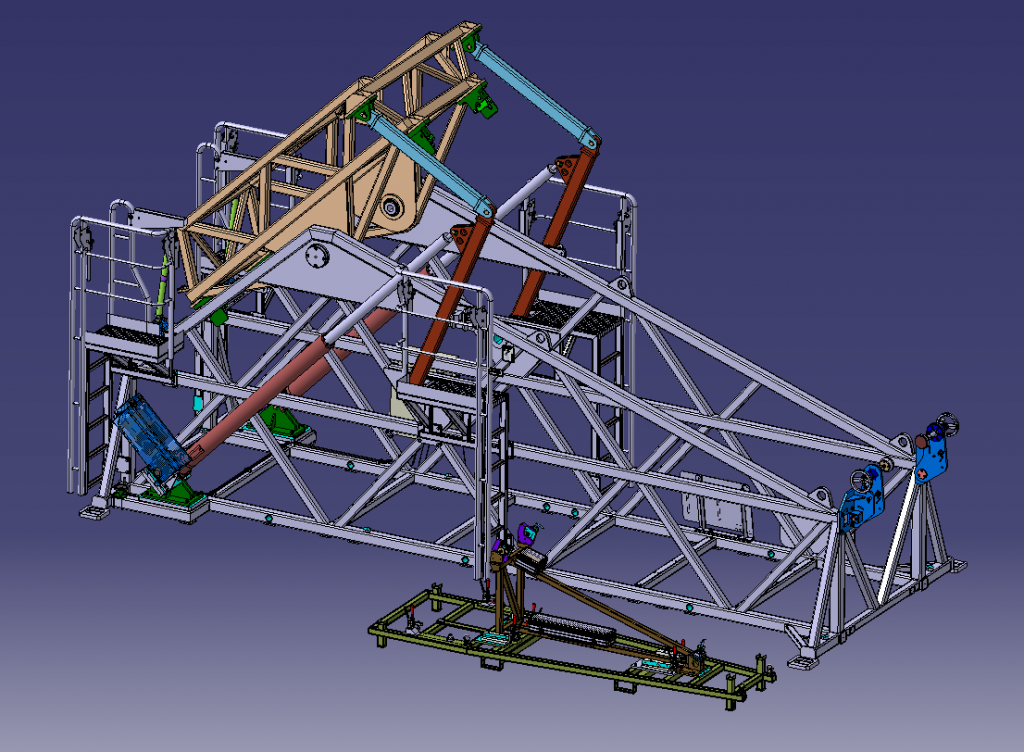

Maintenance of JIG’s and basements

Beluga transport equipment

With the experience of our engineers and technicians with the BELUGA transport equipment and our hi-tech devices and tools, we are able to overhaul, upgrade, adapt and commission all the transport equipment in the fleet used to deliver aircraft parts between AIRBUS factories throughout Europe.

Our technicians are certified in the following areas: welding- including aluminium, NDT, laser tracker measurement, and much more.

This level of quality makes it possible for all our services to meet global technical requirements and also to directly and verifiably provide the special certifications requested by our customers.

- Flexible use of the latest measurement technology

- Design using Inventor 3D-CAD and Catia V5

- Engineers specialised in and trained by Duwe3D

- Reverse Engineering

- Measurement technology by FARO

- Faro Vantage laser tracker

- Faro laser scanning arm

- Specially processed according to customer requirements with the software PolyWorks