Rapid renovation on-site

We can also carry out all valve renovations directly at the customer’s premises using the on-site machining process. This makes repairs much more flexible and thus more cost-effective. This is how we can immediately meet the requests of our customers using customised maintenance on demand and minimise any possible downtimes. Due to the special design of our metal-working machines, almost all mechanical machining of valve components is possible.

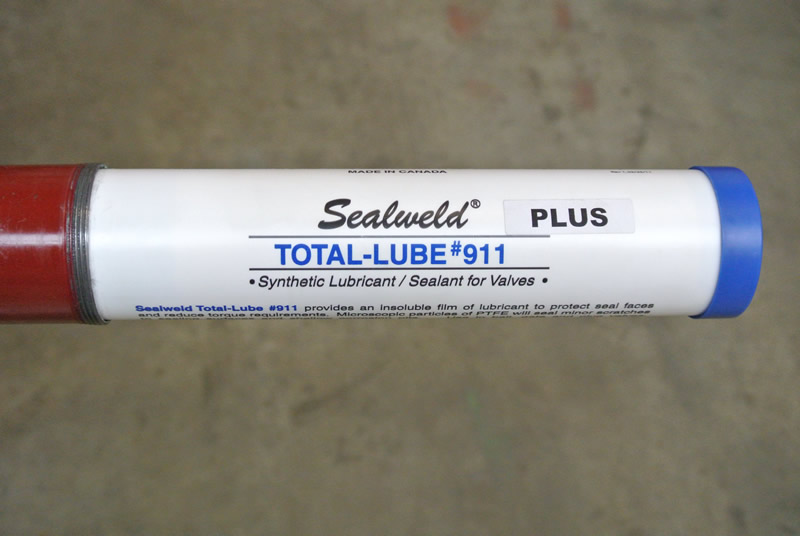

This process makes it possible to treat installed and pressurised valves and significantly improve the tightness. The sealing system is suitable for most brands. With our decades of experience, we have optimised our expertise, products and processes and are therefore able to seal 98% of all valves.

Emergency leak sealing of valves by our valve specialists

Our processes enable our valve specialists to introduce a special cleaner and sealant into a valve. It is not necessary to remove the affected valve for these procedures.

This process makes it possible to treat installed and pressurised valves and significantly improve the tightness.

- Leakage at seat rings

- Leakage at the switch pin

- Leakage at the housing

- Leakage in the head gasket

Mobile machinery

- Slide grinding and lapping machines

- Valve grinding and lapping machines

- Portable lathes

- Flange and processing machines

- Seat machining equipment

- Hydraulic tools

- Welding machines

- Workshop and tool container

- Sandblasting equipment

- Safety valve testing equipment

- Pressure and leak test stands

The TDF-2 is a portable machine for the turning of flanges with flat and conical sealing surfaces. Due to its very flat design, the TDF-2 is also suitable for on-site machining of flanges in piping systems.

The machine has both a facing head and an angular turning head for the machining of tapered surfaces.

- Machining diameter: 300 mm to 1,200 mm

- Mounting diameter: 485 mm to 1,345 mm

- Machine height: 350 mm

- Radial stroke: 100 mm

- Automatic radial feed (fine/coarse): 0.1/1.0mm

- Rpm adjustment: 20 mm

- Axial stroke with angle head (optional): 80 mm