Requirement planning is crucial

Plant standstills are just as much a part of the life cycle of a plant as production peaks. Proven practice to this day: Personnel requirements planning for the upcoming maintenance work, based on the experience of the responsible plant engineers and technicians. Of course, the duration of the standstill must be as short as possible in order to minimise production losses. The skills and knowledge of the standstill coordinator are of utmost importance here.

All-inclusive package for your plant maintenance

The know-how we have acquired over decades in various large-scale plants allows us to provide services for our customers in a particularly flexible and cost-effective manner. You as a customer save time and personnel resources – and thus shift the responsibility for costs to Relais Control. We guarantee the planning, implementation and documentation in accordance with the agreed maintenance and service specifications, thus significantly reducing your downtime costs. Warranty clauses can be agreed depending on the scenario of the plant standstill. In this way Relais Control offers you an all-inclusive package in plant maintenance – and meets your requirements for customised maintenance.

Our engineering services in detail

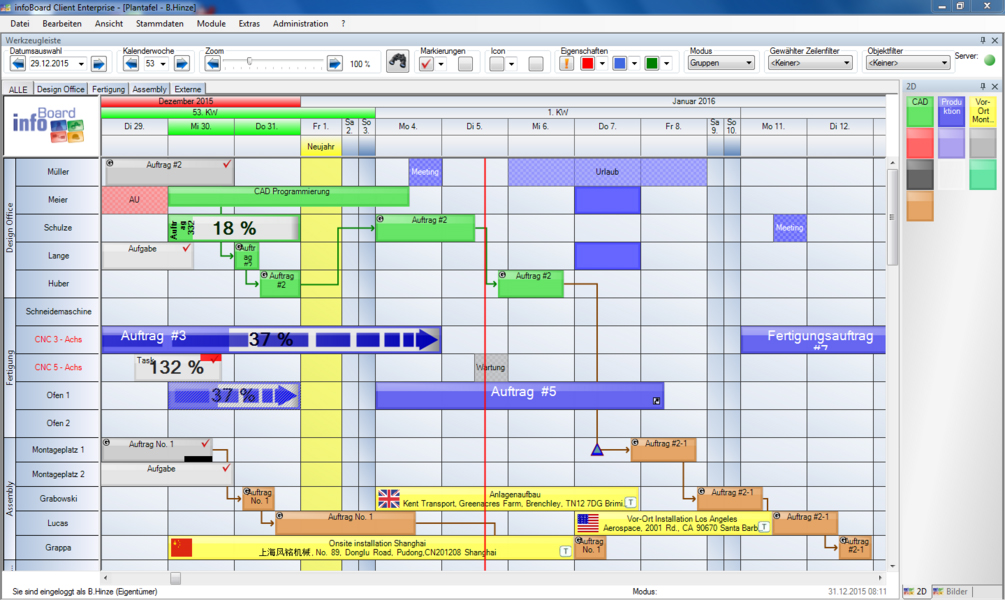

- Creation of a schedule

- Work preparation

- Determination of the work content

- Creation of maintenance instructions with performance description and parts lists for all trades involved

- Resource planning (material / personnel) and disposition

- Procurement and provision of material and tools

- Execution of the work according to the schedule of services

- Coordination of the participating specialist trades

- Project coordination and monitoring

- Advice on utilisation and reutilisation of existing valves under consideration of the current technical status

- PC-supported creation of specification-compliant

- quality assurance documents for repairs, renovations and spare parts

- PS-supported creation of Master QA documents for revision work

- Conducting approval discussions with customers and authorities

- Computer-supported recording, evaluation and management of all valve data

- with specially developed software

- Valve database

- Damage investigation and cause determination with final report

- Material investigation to determine the degree of fatigue and determination the expected remaining service life

- Creation of CAD drawings using AutoCAD Inventor

- 3D modulation

- Stress calculation